Retail forecasting has always been positioned as a planning discipline. Predict demand accurately, align inventory to it, and retail operations should run smoothly.

Yet the reality looks very different.

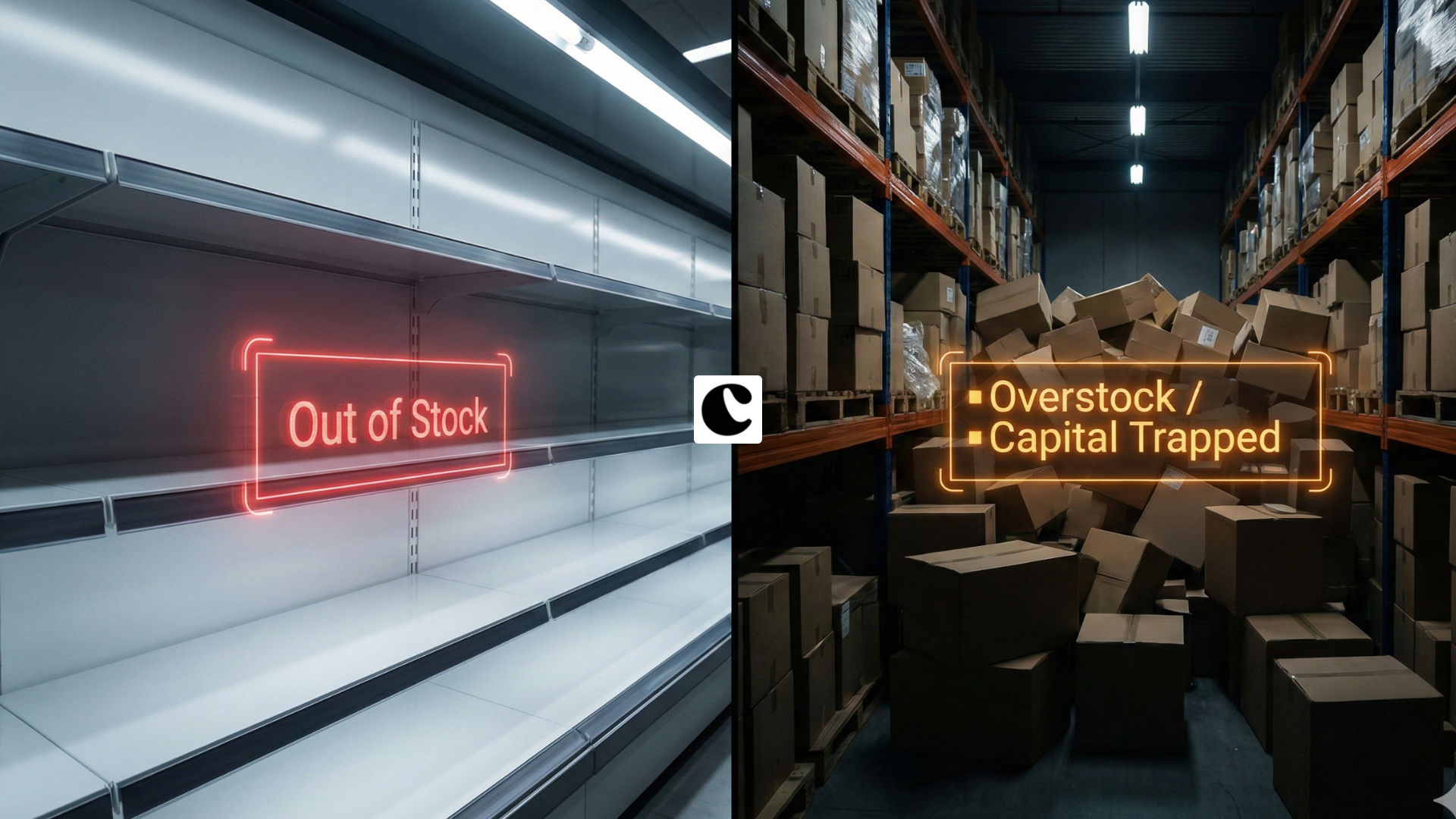

According to IHL Group The twin failures of out-of-stocks and overstocks now cost the global retail economy approximately USD 1.8 trillion every year, a number roughly equivalent to the GDP of Brazil. This loss is not theoretical. It shows up as missed sales, heavy markdowns, wasted inventory, frustrated customers, and burned margins.

Despite decades of investment in forecasting tools, retailers continue to plan with surprising blind spots. To understand why, we need to examine both the economic cost of failure and the structural limits of traditional forecasting models.

Retail forecasting is the process of predicting future customer demand to guide decisions across buying, merchandising, inventory planning, and supply chain operations. These forecasts determine:

As retail cycles accelerate and assortments expand, forecasting failures are no longer isolated planning errors. They signal a broader breakdown in the merchandising system itself, one that is unable to operate at the speed modern retail now requires.

The most immediate impact of poor forecasting appears directly on the P&L through lost revenue and rising carrying costs. This is commonly referred to as inventory distortion, but functionally it reflects a mismatch between how fast demand forms and how slowly supply reacts.

When a customer encounters an empty shelf or an “out of stock” message, revenue is lost instantly. Industry estimates suggest that stockouts represent a large share of the USD 1.8 trillion annual loss.

For high-velocity SKUs, even a small forecasting error can result in thousands of dollars in lost sales per store per week. More importantly, the true cost is not revenue, but margin. In low-margin categories such as grocery, a stockout on a high-margin item disproportionately damages profitability.

Many retail leaders are now reassessing whether forecasting sits in the right place within their merchandising operating model. Couture.ai often explores this question with planning and merchandising teams in focused working sessions.

When forecasts overshoot, capital becomes locked in excess inventory. Holding costs including warehousing, insurance, shrinkage, and taxes, can reach 20–30 percent of inventory value annually.

Overstock inevitably leads to markdowns. Every discount applied to clear inventory is a direct hit to margin. In fast fashion and seasonal categories, unsold inventory may have little or no residual value, contributing to both financial and environmental waste.

The more dangerous costs of forecasting failure are long-term and often invisible.

Modern consumers have a very low tolerance for unavailability. Research shows that a majority of customers will switch retailers if they cannot find what they want, and very few are willing to wait for a restock. A single stockout can permanently break loyalty.

Marketing inefficiency compounds the problem. Retailers frequently spend heavily to drive traffic to products that are not adequately stocked. Every click that leads to an unavailable product erodes return on ad spend and increases customer acquisition cost.

For decades, retailers have relied on deterministic forecasting models such as ARIMA (AutoRegressive Integrated Moving Average) and exponential smoothing. These models are built on a core assumption: the future will resemble the past.

When a TikTok trend spikes demand overnight, or a supply route is disrupted unexpectedly, legacy models do not just perform poorly. They fail silently, often triggering bullwhip effects across the supply chain.

Traditional statistical models assume that demand patterns are stationary, meaning their statistical properties remain stable over time. In reality, modern retail demand is non-stationary and driven by irregular, non-linear events.

A sudden influencer endorsement, an unseasonal heatwave, or a competitor’s flash sale can fundamentally reshape demand in ways historical averages cannot anticipate.

Legacy models assume linear relationships between variables. Retail demand rarely behaves this way.

For example, a promotion combined with a weather change can produce demand far greater than either factor alone. Linear models see these effects as additive. Reality is often multiplicative.

When sales drop due to stockouts, legacy models interpret this as declining demand. They reduce future forecasts, reinforcing under-ordering and deepening the problem. The model lacks context to distinguish true demand from constrained sales.

Omnichannel retail introduces a level of complexity that spreadsheets and traditional models cannot handle.

Inventory, forecasting, and fulfillment often operate in silos. Retailers may run out of stock online while identical inventory sits unsold in nearby stores. Aggregate forecasts mask fundamentally different demand patterns, such as subscription replenishment versus impulse buying.

Without a unified view, retailers lose sales despite owning the inventory. Some retailers are addressing this by rethinking forecasting as part of a broader Trend → Store architecture. Couture.ai regularly works with leadership teams to map where forecasting breaks down across this lifecycle.

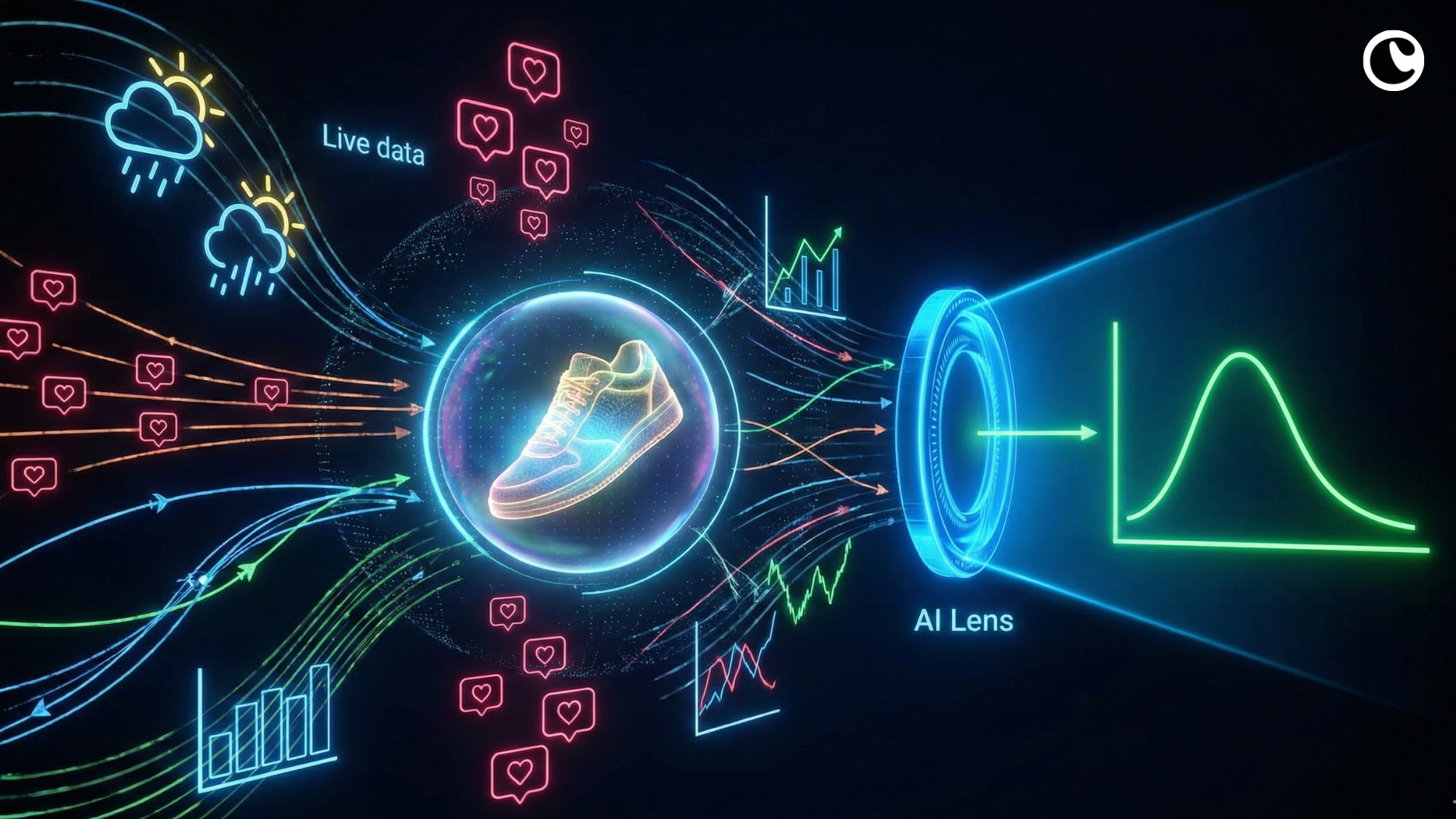

Artificial intelligence represents not an incremental improvement, but a fundamental shift from forecasting to demand sensing.

Instead of producing single-point predictions, AI generates probabilistic scenarios that reflect uncertainty and risk.

Modern architectures, including transformer-based models originally developed for language understanding, allow systems to interpret context. Just as language models understand meaning within a sentence, these systems understand demand within their real-world environment.

Leading retailers have already demonstrated the value of this shift.

These examples show that AI forecasting is no longer experimental. It is becoming the operational standard.

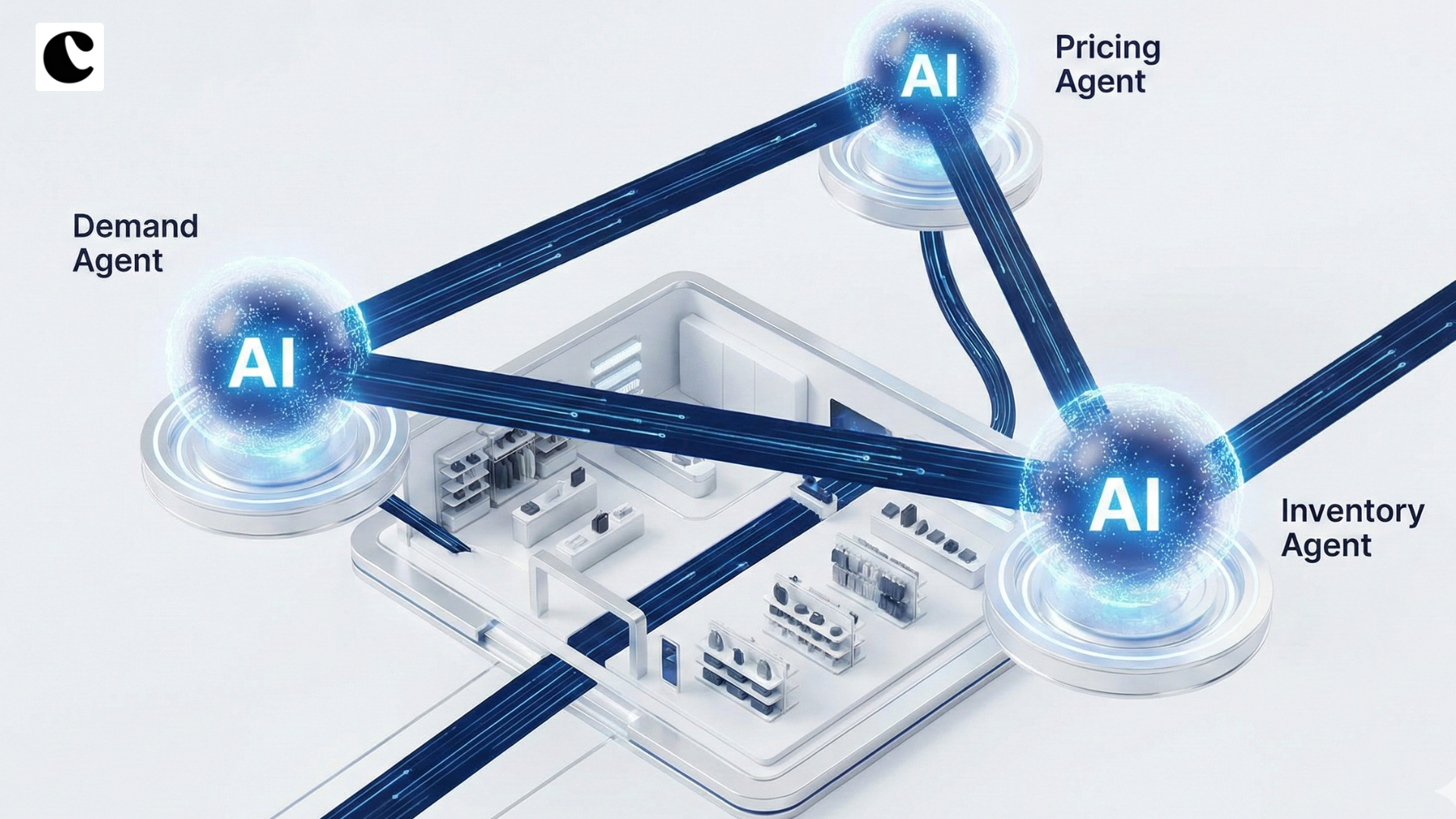

The most important shift is not better models, but better integration.

In modern systems such as Couture.ai, forecasting operates as part of an agentic merchandising architecture. Trend detection, demand sensing, allocation, replenishment, and pricing are coordinated through a unified intelligence layer.

Forecasting no longer produces reports. It drives action.

As the industry moves toward 2025, AI is expanding from backend optimization to autonomous decision-making.

Agentic AI systems will negotiate replenishment, adapt assortments in real time, and optimize logistics while balancing cost, speed, and sustainability. Generative AI will enable scenario modeling and synthetic data creation, solving long-standing cold-start problems for new products.

Retailers will increasingly compete not on who forecasts better, but on who reacts faster and executes smarter.

Retail forecasting continues to fail because it is often treated as a disconnected analytical function inside fragmented merchandising processes.

AI fixes this not by predicting better in isolation, but by embedding forecasting into an autonomous, agentic merchandising system where trend discovery, demand sensing, and execution operate as one.

To explore how agentic AI can turn forecasting into a real-time decision engine, Couture.ai shares deeper perspectives on autonomous merchandising. Start a strategic discussion with us!

Subscribe to get the latest updates and trends in AI, automation, and intelligent solutions — directly in your inbox.

Stay Informed: Insights and Trends from Couture AI

Reduce operational complexity, improve planning accuracy, and deliver smarter retail execution with Couture AI.